Cleaning and maintaining PCB (Printed Circuit Board) is an important step to ensure its performance and life. The following are detailed cleaning and maintenance methods:

Cleaning PCB circuit boards

Required Materials and Tools

- Anti-static brush : For initial removal of dust and large residues.

- Specialized electronics cleaners : such as Flux Remover, designed to clean flux residues.

- Isopropyl alcohol (99%) : A commonly used solvent suitable for most cleaning tasks.

- Lint-free cloth : Anti-static wipes to avoid leaving fibers.

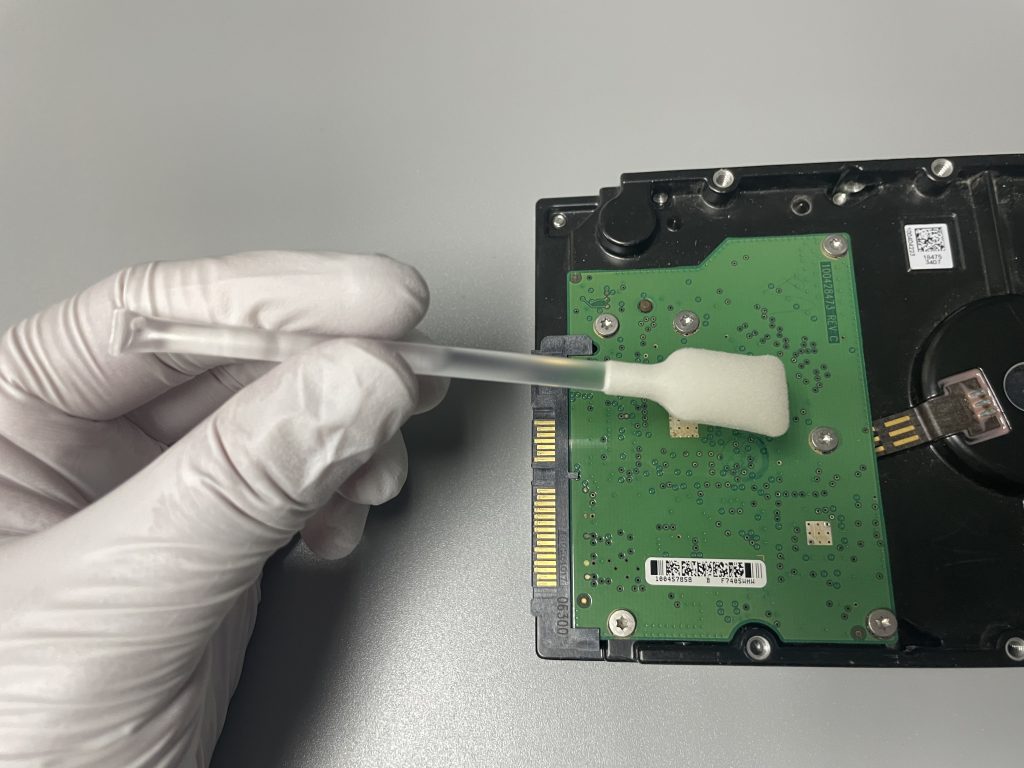

- Sponge and cloth swabs : Hard-wearing, low-lint, suitable for delicate cleaning.

- Ultrasonic Cleaner : For high volume cleaning.

Cleaning steps

- Initial cleaning :

- Use an anti-static brush to gently brush away dust and large pieces of flux residue from the circuit board.

- Solvent Cleaning :

- Use a sponge swab or lint-free cloth dipped in isopropyl alcohol or a proprietary electronics cleaner to clean any areas of flux residue.

- Use a new cotton swab to avoid redistributing flux residue.

- Deep Cleaning :

- For hard-to-clean areas, the board can be placed in an ultrasonic cleaner using appropriate detergents and deionized water for a deep clean.

- Secondary cleaning :

- Wipe the cleaned area with a lint-free cloth or dry sponge swab to remove solvent residue and avoid streaks.

Maintaining PCB circuit boards

99% Isopropyl Alcohol is an ideal choice for cleaning and maintaining electronic devices, optical devices, and other water-sensitive components due to its fast evaporation and residue-free properties. Proper use of 99% Isopropyl Alcohol ensures that cleaning tasks are completed efficiently and safely while avoiding any damage to the device.

Regular Inspection and Maintenance Procedures

- Dust cleaning :

- Regularly use an anti-static brush or compressed air to clean dust off the circuit board to prevent dust accumulation from affecting heat dissipation and performance.

- Electrolytic capacitor inspection :

- Check the electrolytic capacitors on the circuit board. If the capacity is less than 20% of the nominal capacity, the capacitor should be replaced. Generally speaking, the life of an electrolytic capacitor is about ten years.

- High-power device heat dissipation silicone grease inspection :

- Check whether the thermal grease on the high-power device is dry. If it is dry, remove the old grease and reapply new grease to ensure good heat dissipation performance.

- Solder joint and connection inspection :

- Check the solder joints and wires regularly to make sure there are no cold solder joints or broken wires. Resolder if necessary to ensure the electrical connections of the circuit board are intact.

- Overall inspection of the circuit board :

- Regularly inspect the entire circuit board to check for corrosion, physical damage or other abnormal conditions, and repair or replace them in a timely manner.

other suggestion

- Anti-static measures : During operation and cleaning, always take anti-static measures to prevent static electricity from damaging the circuit board.

- Use high-quality materials : Use high-quality cleaners, swabs, and tools to ensure effective cleaning and reduce damage to the circuit board.

- Keep the environment clean : When cleaning and maintaining circuit boards, keep the working environment clean to reduce re-contamination by dust and dirt.

When it comes to the maintenance and cleaning of electronic devices, choosing the right cleaning agent is crucial. Many common cleaning products contain water, which is undoubtedly a potential threat to some sensitive electronic components. However, using 99% isopropyl alcohol (IPA) cleaning agent can perfectly solve this problem and provide excellent cleaning results for your electronic devices.

Through these cleaning and maintenance steps, the service life of the PCB circuit board can be effectively extended and its stable operation can be ensured.